Circuit Board Manufacturing & PCB Assembly & Electronic Assembly service & khamphani e etsang lisebelisoa tsa elektroniki - XinDaChang Co., Limited

E le mofani ea etelletseng pele oa litšebeletso tsa Kopano ea PCB naheng ea China, At XinDaChang e fana ka lihlahisoa tsa boleng bo holimo, tse theko e tlaase ebile e fana ka tlhahiso ea PCB, tlhahiso ea kopano ea lisebelisoa tsa elektroniki, ho fumana likarolo, kopano ea Box Building le lits'ebeletso tsa tlhahlobo ea PCBA bakeng sa bareki ba rona.

Bakeng sa kopano e felletseng ea boto ea potoloho ea senotlolo, re hlokomela ts'ebetso eohle, ho kenyeletsoa ho etsoa ha Maboto a Potoloho a Khatisoang, ho fumana likarolo, ho latela taelo, ho lekola boleng le kopano ea ho qetela ea boto ea PCB. Athe bakeng sa senotlolo sa karolo e itseng, moreki a ka fana ka li-PCB le likarolo tse itseng, 'me likarolo tse setseng li tla sebetsoa ke rona.

PCB kopano ke eng

Boto ea potoloho pele ho kopano ea likarolo tsa motlakase e bitsoa Printed Circuit Board. Ka mor'a ho soasoa ha lintho tsohle tse holim'a boto, e tsejoa e le Printed circuit Board Assembled, re ile ra bitsaKopano ea PCB. Ts'ebetso e felletseng ea kopano ea karolo e bitsoa Printed Circuit Assembly kapa Printed Circuit Board kopano kapa kopano ea boto ea PCB. Ts'ebetsong ena, ho sebelisoa lisebelisoa tse fapaneng tsa ho kopanya le tsa matsoho. Re assembler e fanang ka kopano ea PCB.

Lipotso bakeng sa XinDaChang - Litšebeletso tsa Kopano ea PCB

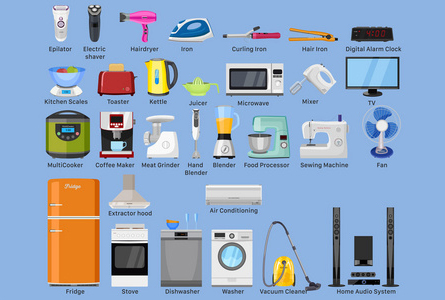

HiTech Circuits e ipabola ka ho fana ka litšebeletso tse felletseng tsa kopano ea Printed Circuit Board (PCB). Sena se kenyelletsa kopano ea thekenoloji ea holim'a metsi (SMT), kopano ea theknoloji ea ka-hole (THT), kopano ea theknoloji e tsoakiloeng, kopano ea prototype, tlhahiso ea molumo o tlaase ho ea holimo, le tharollo ea turnkey. Litšebeletso tsa rona li etselitsoe ho fana ka mefuta e mengata e fapaneng ea liindasteri, ho kenyelletsa empa e sa felle feela ho likhokahano tsa mehala, lisebelisoa tsa bongaka, likoloi, le lisebelisoa tsa elektroniki tsa bareki.

E, re fana ka litšebeletso tse feletseng tsa kopano ea turnkey PCB. Sena se bolela hore re ka khona ho laola mohato o mong le o mong oa projeke ea hau ho tsoa ho lisebelisoa tsa ho fumana thepa, tlhahiso ea PCB, kopano, liteko le thomello ea ho qetela. Tharollo ea rona ea turnkey e etselitsoe ho u bolokela nako le ho fokotsa bothata ba ho hokahanya le barekisi ba bangata.

Ruri! Re na le theknoloji e tsoetseng pele ea tlhahiso 'me re na le sehlopha se nang le tsebo se khonang ho sebetsana le likopano tse rarahaneng tsa PCB. Hore na morero oa hau o kenyelletsa likhokahanyo tse phahameng tsa "high-density interconnects" (HDI), likarolo tse ntle tsa molumo, kapa o hloka mekhoa e khethehileng ea ho hlabolla, re na le boiphihlelo le lisebelisoa ho fihlela litlhoko tsa hau.

Re sebelisa ts'ebetso e matla ea netefatso ea boleng e kenyelletsang tlhahlobo ea optical inspection (AOI), tlhahlobo ea X-ray, tlhahlobo ea potoloho (ICT), le tlhahlobo ea ts'ebetso ho bona le ho lokisa liphoso kapa mathata afe kapa afe. Mehato ea rona ea ho laola boleng e ntse e le boemong bo bong le bo bong ba ts'ebetso ea kopano ho netefatsa hore kopano e 'ngoe le e' ngoe ea PCB e finyella litekanyetso tsa rona tse phahameng le litlhoko tsa hau tse khethehileng.

HiTech Circuits e ikemiselitse ho fana ka lihlahisoa tsa boleng bo holimo. Re netefalitsoe tlasa ISO 9001 bakeng sa sistimi ea rona ea taolo ea boleng, ho netefatsa hore lits'ebetso le lihlahisoa tsa rona li fihlela maemo a machaba a boleng le ho ts'epahala.

Bakeng sa qotso e qaqileng le e nepahetseng, ka kopo re fe lifaele tsa hau tsa moralo tsa PCB (Lifaele tsa Gerber, BOM (Bili ea Thepa), litšoantšo tsa kopano, le litaelo kapa litlhoko tse ikhethileng tseo u nang le tsona.

Ee, kopano ea mohlala ea PCB ke e 'ngoe ea litšebeletso tsa rona tsa mantlha. Prototyping e u lumella ho leka le ho ntlafatsa meralo ea hau pele u fallela tlhahisong ea bongata. Re fana ka linako tse potlakileng tsa phetoho bakeng sa li-prototype ho thusa ho potlakisa potoloho ea hau ea nts'etsopele.

Re ikemiselitse ho fana ka litheolelo kapele kamoo ho ka khonehang. Ka tloaelo, o ka lebella ho fumana qotsulo e felletseng nakong ea lihora tse 24 ho isa ho tse 48 kamora ho fana ka litokomane tsohle tse hlokahalang le tlhaiso-leseling mabapi le projeke ea hau.

Ee, re utloisisa bohlokoa ba ho kopana le linako tse behiloeng tse tiileng mme re ka amohela litaelo tse potlakileng tsa kopano ea PCB. Ka kopo ikopanye le rona ka litlhoko tsa hau tse ikhethileng, 'me re tla etsa sohle se matleng a rona ho fihlela kemiso ea hau ea nako ntle le ho sekisetsa boleng.

Re lumela ho boloka bareki ba rona ba tsebisitsoe mohato o mong le o mong oa tsela. Hang ha odara ea hau e behiloe, o tla abeloa mookameli oa morero eo e tla ba sebaka sa hau sa puisano. U ka lebella lintlafatso tsa khafetsa mabapi le boemo ba odara ea hau 'me u lula u amohelehile ho ikopanya le mookameli oa projeke bakeng sa lipotso leha e le life kapa lintlafatso.

Theknoloji ea rona

Ho XinDaChang, re sebelisa likhatelopele tsa morao-rao tsa theknoloji bakeng sa kopano ea rona ea boto ea potoloho e hatisitsoeng. Tse ling feela tsa theknoloji le mechini eo re e sebelisang e kenyelletsa:

• Mochini oa solder oa maqhubu

• Khetha le ho beha sebaka

• AOI & X-Ray

• Ho roala ka mokhoa o ikemetseng

• Mochini oa SPI

Kopano ea Surface Mount Technology (Seboka sa SMT)

Ho XinDaChang, re na le bokhoni ba ho sebelisa theknoloji ea holim'a marulelo ho bokella li-PCB tsa hau, re sebelisa mochini oa rona oa ho khetha le ho beha. Re sebelisa thekenoloji ea kopano ea holim'a thaba kaha e na le litšenyehelo tse ngata ebile e tšepahala ho feta mekhoa e meng e tloaelehileng ea kopano ea PCB. Ka mohlala, ka kopano ea SMT lisebelisoa tse ngata tsa elektronike li ka kenyelletsoa sebakeng se senyenyane ho PCB. Sena se bolela hore li-PCB li ka etsoa habonolo le ka mokhoa o atlehileng haholoanyane, le ka molumo o phahameng haholo.

Teko le taolo ea boleng

Ho netefatsa hore ts'ebetso ea kopano ea PCB ha e na liphoso, re sebelisa tlhahlobo le tlhahlobo ea AOI le X-Ray. AOI, kapa tlhahlobo ea optical e ikemetseng, e lekola li-PCB bakeng sa ho hloleha ho hoholo le bofokoli ba boleng ka ho li skena ka kh'amera e ikemetseng. Re sebelisa tlhahlobo e ikemetseng ka mekhahlelo e mengata ea ts'ebetso ea kopano ea PCB ho netefatsa hore li-PCB tsa rona kaofela ke tsa boleng bo holimo.

Flexible Volume PCB Kopano ea Tšebeletso

Litšebeletso tsa rona tsa kopano ea PCB li feta seo k'hamphani e tloaelehileng ea kopano ea PCB e tla se etsa. Re fana ka mefuta e fapaneng ea litšebeletso tsa kopano ea boto ea potoloho bakeng sa mekhahlelo e fapaneng ea nts'etsopele ea sehlahisoa sa hau, ho kenyelletsa:

• Prototype PCB Assembly: Bona hore na moralo oa hau oa PCB o sebetsa hantle hakae pele o etsa odara e kholo. Kopano ea rona ea boleng ba PCB e re lumella ho fana ka setšoantšo se potlakileng, kahoo o ka tseba liphephetso life kapa life tse ka bang teng moralong oa hau le ho ntlafatsa boleng ba liboto tsa hau tsa ho qetela.

• Molumo o Monyenyane, High Mix PCB Assembly: Haeba o hloka palo ea liboto tse fapaneng bakeng sa lisebelisoa tse khethehileng, HitechPCB ke k'hamphani ea hau.

• Phatlalatso ea PCB e Phahameng ka ho Fetisisa: Re na le tsebo e tšoanang ea ho ntša liodara tse kholo tsa kopano ea PCB ha re ntse re fana ka tse nyenyane.

• Kopano ea PCB e Laetsoeng le e sa Feleng: Litšebeletso tsa rona tsa kopano ea PCB tse rometsoeng li finyella litekanyetso tsa IPC Class 2 kapa tsa IPC tsa sehlopha sa 3, li netefalitsoe ke ISO 9001:2015 'me li lumellana le RoHS.

• Full Turnkey PCB Assembly: Hape ISO 9001: 2015-certified le RoHS-e lumellana, kopano ea rona ea turnkey PCB e re lumella ho hlokomela morero oa hau kaofela ho tloha qalong ho fihlela qetellong, e le hore u ka kenella 'me u qale ho sebelisa monyetla oa sehlahisoa se felileng hang-hang.

Ho tloha ho SMD ho isa ho merero e kopaneng ea PCB, re e etsa kaofela, ho kenyelletsa le licheke tsa mahala tsa Valor DFM/DFA le tlhahlobo ea ts'ebetso ho netefatsa boleng ba liboto tsa hau, ntle le litlhokahalo tse tlase tsa litšenyehelo kapa litefiso tse ekelitsoeng tsa lisebelisoa ha o hlophisa bocha.

XinDaChang e kopanya litsamaiso tse netefalitsoeng tsa ISO le mekhoa e mecha ea ho kopanya le ho paka ho fana ka lihlahisoa tsa elektroniki tsa bareki tse etellang pele 'marakeng. Ho tloha ho kopano ea lihlahisoa ho ea ka liphaello ho isa litekong le ho paka, mehala ea SMT ea Hitech e sebelisa mahlale a tsoetseng pele indastering ho kenyelletsa:

Phutheho e potlakileng ea pcb kopano ea Flip Chip Technologies

0201 Theknoloji

Theknoloji ea Solder e sa Lebelloang

Mefuta e meng ea PCB e Felisa

Ho kenya letsoho ha mofani oa thepa pele ho nako

Tšehetso ea moralo le boenjiniere

Tlhahiso ea PCB le kopano ea PCB

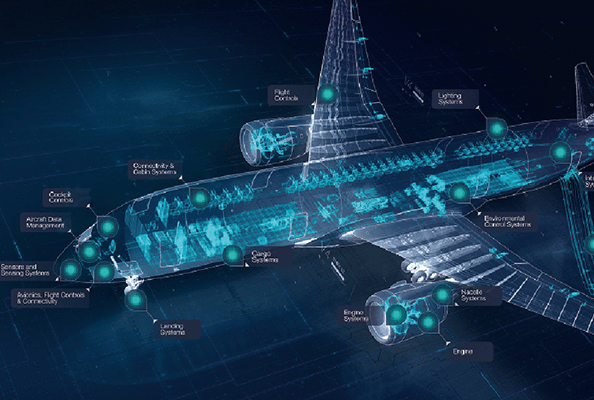

Kopano ea sefofane

Memori ea memori le optical

Kopano ea lithapo le likhoele

Ho bopa ente ea polasetiki

Ho sebetsa ka nepo

Libaka tse koaletsoeng

Ho kopanya hardware le software

Litšebeletso tsa BTO le CTO ho latela litlhoko tsa hau

Teko ea ho tšepahala

Mekhoa ea boleng ba Lean le Six Sigma

Phapano ke efe pakeng tsa Printed circuit board vs PCB Assembly?

PCB ke boto ea potoloho e hatisitsoeng hobane e entsoe ka khatiso ea elektronike, kahoo e bitsoa "boto ea potoloho" e hatisitsoeng. PCB ke karolo ea bohlokoa ea elektroniki indastering ea elektroniki, ke setsi sa elektroniki. Ke ts'ehetso ea likarolo tsa elektroniki le mojari oa khokahano ea motlakase ea likarolo tsa elektroniki. PCB e sebelisitsoe haholo tlhahisong ea lihlahisoa tsa elektroniki.

Seboka sa PCB ka kakaretso se bua ka phallo ea ts'ebetso, eo hape e ka utloisisoang e le boto ea potoloho e felileng, ke hore, PCBA e ka baloa feela kamora hore lits'ebetso tsa PCB li phetheloe. PCB e bua ka boto ea potoloho e hatisitsoeng e se nang letho e se nang likarolo ho eona. Ka holimo ke phapang pakeng tsa PCB le PCBA.

SMT (theknoloji e phahamisitsoeng holim'a sefahleho) le DIP (Dual In-line Package) ke litsela tse peli tsa ho kopanya likarolo ho boto ea potoloho. Phapang e kholo ke hore SMT ha e hloke ho phunya masoba ho PCB, empa ha e qoelisoa, e hloka ho kenya phini ka mokoting o phuntsoeng.

SMT haholo-holo e sebelisa mochini o kenyang ho kenya likarolo tse nyane le tse nyane botong ea potoloho. Ts'ebetso ea eona ea tlhahiso ke boemo ba PCB, khatiso ea solder paste, e kenngoa ka mochini o ntseng o hola, ontong ea reflow, le tlhahlobo.

Dip ke "plug-in", ke ho kenya likarolo letlapeng la PCB. Ke mofuta oa karolo e kopantsoeng ea plug-in ha likarolo tse ling li le kholo ka boholo 'me li sa tšoanelehe bakeng sa theknoloji e ntseng e eketseha. Mekhoa ea eona e ka sehloohong ea tlhahiso ke sekhomaretsi sa morao, plug-in, tlhahlobo, wave soldering, brushing plate, le tlhahlobo e felileng.